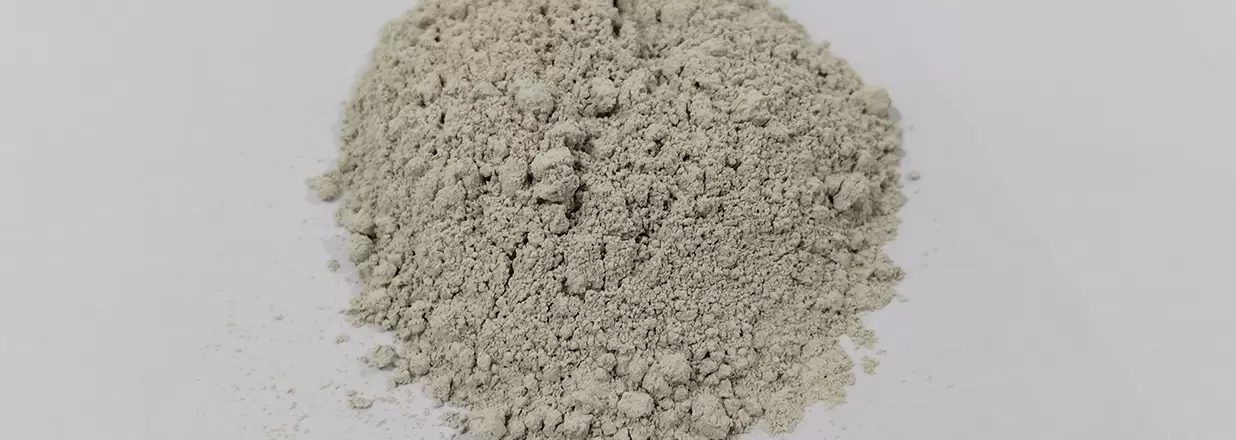

Gypsum Powder For Moulding is created using plaster made of gypsum, which may or may not be reinforced with steel, burlap, jute, or glass fibres, depending on the intended use. Gypsum Mouldings are designed to improve the architectural value of a building’s interior and exterior, whether it be a hospital, a conference room, a movie theatre, or something else entirely.

Natural Gypsum Powder that is used for moulding is of high quality. It does not set up too quickly, and the mould that it produces is very sturdy. It is chemically pure. The solution’s ratio of water to gypsum should be as low as possible, and the solution itself should be sucked to produce a mould of the highest possible quality.

The moulds have to be dried at a temperature not higher than 60 degrees Celsius. The ratio of water to gypsum powder for moulding causes a linear increase in the porosity of the moulds. It causes an increase in the water and air permeabilities while simultaneously causing an apparent decrease in density. It is not recommended to keep gypsum. A mould made from fine gypsum powder provides a higher building-up rate for the casting. The building-up rate of the casting is unaffected by variations in the porosity of the moulds that fall within the range of 40–70 percent.

Gypsum Powder Suppliers

We are leading gypsum powder suppliers in India. We also provide gypsum over the world. When doing run-in-place ornamental work like cornices, moulding plaster is used in conjunction with lime putty, which is made by mixing two parts lime with one part moulding plaster by weight. Along with gypsum powder manufacturer, we also manufacture steel shots, aluminium oxide, quartz sand, sand blasting machine, grit blasting machine, stainless steel shots, aluminium wire, zinc metalizing wire, arc spray gun, flame spray gun, thermal spray metalizing wire and other abrasive media.

Gypsum Powder Price

Gypsum powder price depends on various things. Gypsum powder is very durable for plasters, agriculture, food, fertility, building and so on. We provide high-quality and pure gypsum powder. Call us to get more details about product and pricing

Gypsum Powder Casting For Moulding

- Preparing a gypsum mould includes moulding, correcting, primarily reinforcing, and reinforcing.

- Drying and roasting include charging the prepared gypsum mould and heating it to a temperature between 120 and 200 degrees Fahrenheit.

- Smelting and pouring entail selecting a smelting furnace by the smelting quantity to rapidly smelt a metal material, increase the metal material’s temperature, and simultaneously maintain the roasting temperature of a casting ladle.

- It decided to use a mould made of gypsum so that not only could the price be brought down, but the issues of poor air permeability and sand cracking in the gypsum could be alleviated to a greater extent. The process of gypsum casting powder with gypsum moulds has a wide range of applications.

Different Types Of Gypsum Powder

- Pink Gypsum Powder

- Green Gypsum Powder

- Fine Gypsum Powder

- Pure Gypsum Powder

Benefits Of Gypsum Powder For Moulding

- Workability – Gypsum is a significantly simpler material to work with compared to concrete. On-site creation of even the most intricate decorative patterns is possible and usually takes no more than half an hour. Because of this, competent builders have the flexibility to create nearly any shape or design that is required for your project without having to wait for concrete pieces to cure for hours or days.

- Cost-Effectiveness – Although working with gypsum mouldings takes a significant deal of skill and experience, the materials and methods involved are very cost-efficient. Because the planning and installation of the project are so simple, you will spend less money on labour, which will help you keep your costs down overall.

- Consistent Results – The traditional method of applying concrete plaster generates a substantial amount of heat, which can cause the finished product to display stress cracks. Gypsum plaster hardens at temperatures that are significantly lower than other application types, which enables it to provide consistent results free of the defects that would otherwise require the part to be recast. Your project remains on schedule thanks to the dependable product, which eliminates the risk of delays resulting in increased costs.

- Easy to Paint or Seal – Gypsum moulding produces surfaces that are flawlessly smooth and require no additional preparation to be painted or sealed when they are finished. Because of this, it is an excellent choice for decorative components that could play a significant role as focus points in the lobby or stairwells of your building.